Powerful benefits through automation

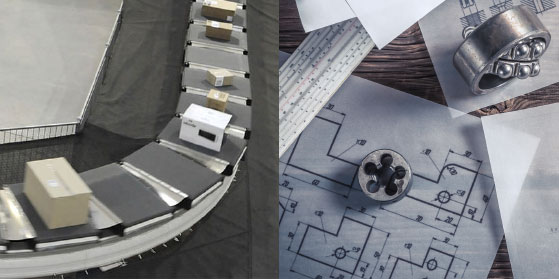

Logistics.

Warehouses and logistic centres are at the heart of the supply chain, often tasked with meeting the virtual 24/7 demands of ecommerce and just-in-time business, while providing a safe and ergonomically friendly working environment for employees.

Automation of today’s distribution centres brings a wide range of benefit from improved workforce productivity, safety and cost effectiveness to greater ability to work in a confined space, reduced customer response times, improved stock tracking and reduced inventory-holding requirements.

I.O. Systems has a proven track record delivering fully and semi-automated solutions for the logistics industry. Our expertise in material handling technology is matched by our experience in software and control engineering. So whether you are planning a greenfield facility, looking to expand, consolidate or further automate operations, we can help you to gain an edge in this competitive market.

Because we deliver customised systems designed to match your precise requirements, all our solutions are unique. However, some of the commonly specified elements include the following:

Conveyors and sorters for pallets and cartons

We have developed a range of automated roller and chain conveyors and automated sorter systems for the transportation and high-speed sortation of pallets or totes and cartons within your distribution centre. Other available warehouse transport solutions include turntables, elevators and pallet cars.

Intelligent order picking solutions

Arriving at an efficient order picking solution for your distribution centre can dramatically increase labour productivity, accuracy and order response times. We can help you choose between approaches such as zone picking, compact picking and integrated picking. Our robotic systems can be integrated with grippers combined with vision, voice and RF or RFID technologies to automate the process.

Stacker cranes for automated racking applications

The range of stacker cranes for automated racking applications includes aisle-bound, cabin and fork cranes, available in single and twin-mast, curve-going, and satellite, multi-deep configurations.

Automatic palletising

Our robotic palletisers automatically stack your packaged goods according to a pre-determined pattern. We can design your system to automate standard, layered and mixed palletising and depalletising operations, according to your requirements. In addition, ancillary systems for packaging, weighing and labelling can be added.

Automated storage and retrieval systems (AS/RS)

Automated storage and retrieval systems (AS/RS) provide the ideal solution where high volumes of loads are being moved into and out of storage, where high levels of picking accuracy are required or where space is constrained.

Pallet storage racks

Specialised racks are required for use with automated pallet stacker crane installations. We offer a choice of in-house or clad racks. The racking can be designed for single-deep, double-deep or multi-deep applications, and gravity-flow storage beds can be incorporated at pick faces. Racking heights of over 40 m are achievable.